Blog Details

Normal Application of Three Way Ball Valve

Normal Application of Three Way Ball Valve

There are two kinds of three-way valves, namely L-port and T-port. L and T represent the path of fluid flow through the three ports, depending on the configuration of the ports and their connections to adjacent pipes.

L-port valves are also called L-pattern valves. The L-pattern describes the fluid flow path as it travels from the inlet to the outlets. Usually, L-port valves have two outlet ports and a single inlet port.

The ports are identified as A, B and AB. Therefore, when port A is used as an inlet, ports B and AB are outlets. If port B is the primary inlet, ports A and AB become the outlets. In other configurations, port AB is the inlet port, while ports A and B act as the outlet ports.

To illustrate how L-ports operate, consider a three-way ball valve with port AB as its inlet. Assume the fluid flows from the inlet port and travels in the right direction towards outlet port B, as illustrated below (Position A). The three-way valve contains a lever or actuator that moves 90 degrees to alternate the direction of fluid flow. When the lever travels 90 degrees clockwise, the ball blocks fluid flow through port B and redirects it towards the left–port A, which becomes the new outlet.

Another quarter turn moves the valves 180 degrees from their original position. At this point, the ball blocks the fluid flow through both outlet ports, and there is a total shutoff to fluid flow. Certain L-port valves can turn 360 degrees and have two shutoff positions. L-ports can be installed in horizontal and vertical configurations. Port AB remains in an open position if the L-port valve is installed in a vertical pipe configuration.

T-Port valves

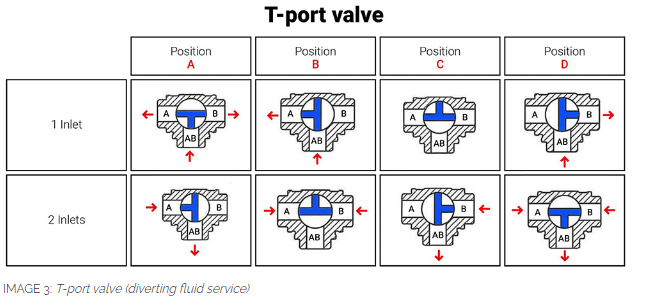

T-port valves are vital for converging (mixing) fluids from two sources and delivering them through a common outlet. The valves are essential for splitting fluids from one source in two directions. Therefore, these valves can have two inlets and a single outlet port or one inlet and two outlets. When using T-ports for fluid control in industrial processes, all the ports are in an open position at once. It implies that the valves can achieve the uninterrupted straight-through flow of service fluids. Like the L-port, T-port valves can fit in vertically and horizontally configured pipelines.

Actuating T-port valves 90 degrees causes them to depict similar performance characteristics as L-port, three-way valves. Fluid will flow from the common inlet and travel through one outlet port alone. Actuating the valve 180 degrees is inconsequential to fluid flow. One shortcoming of T-port valves is their lack of bubble-tight shutoff. These valves are unsuitable for pipelines demanding strict control of leakages and fugitive emissions. T-port valves are fitted with lock handles that control the quarter turn transitions of the flow control mechanisms. This feature facilitates better volumetric control when mixing or diverting service fluids.

Practical Applications of Three-Way Valves

T-port valves are mostly used for mixing services in industrial applications. The valves are connected to pipelines transporting different fluid compositions. As the fluids from the diverse sources merge at the valve, they mix in controlled proportions before moving to subsequent pipe sections or processes. T-port valves usually provide constant flow control, assisting engineers in mixing and sampling fluids at different pipe sections.

Diverting fluid flow is possible using L-port and T-port valves. L-port valves provide a fluid diversion to one direction at a particular time. However, T-port valves can divert fluids to two destinations at once. T-port valves can also allow for straight-through flow (from inlet port A to outlet port B), which could be diverted 90 degrees to the second outlet port AB. It is a common set up in T-port valves used in diverting applications, as this cannot be accomplished with an L-port arrangement. L-port valves can divert fluid between two storage tanks. Once one tank fills up, the valve (if automated) changes its position and directs incoming fluid into the empty tank. Depending on the configuration, T-port valves can also act like L-port valves to divert fluid flow between storage tanks.

Three-way valves can be manually operated or automated using electric, pneumatic or hydraulic actuators.

0 Comments